Inventory Control Management in a Warehouse

| |||||

|

["{div class=objectGalleryCell style=\"background:url(\/images\/wms.jpg) center center \/ cover no-repeat;\"}{img src=\"\/images\/wms.jpg\" style=\"opacity:0;width:100%;height:100%;\"}{\/div}"] |

|

||||

|

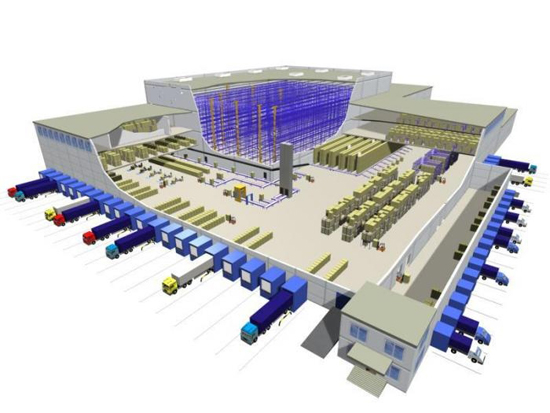

Warehouse inventory control management systems are designed to manage warehouse facility and help staff, vendors and even customers to be aware of the current inventory status. Here is a simple example: a new order for widgets is coming in soon. You stay confident, since you know that a manual inventory, performed last month, shows that product on hand is sufficient to fulfill that order. Still, there is chance that you may not remember a roof leak or any other damage that had already destroyed the material you were counting on. A warehouse inventory management system, however, makes such chances as minimal as possible. With a system like that, an immediate report will be a one-minute thing, showing you relevant up-to-date inventory status and even the place of destroyed inventory disposal (if any). Development of micro computing devices (such as RFID tags) allows managers to keep track of relevant warehousing information. Warehouse management system can become a perfect way of tracking movements of separate items as well as entire pallets of goods. However, to ensure proper implementation you have to work closely with your IT manager, since all of these systems are computer based. WMS system can be either Internet based or based on your company network. To prevent potential mistakes in the future and save costly expenses, you will have to do a thorough survey of system requirements. Most management systems are worth the cost and start paying for themselves soon enough. Another important person to take into account is your warehouse manager. Managers are aware of the product flows and are necessary for the proper software implementation. Your manager will be the primary person, understanding inefficiencies of the plant. They are especially important while expanding your storage place for managing employees who often become overloaded with work. Warehouse managing system can significantly optimize operator's routine. They enable perfect product flow and clear visibility of each item. Such computerized solutions save companies money and human labor. As it was already mentioned, implementation of software inventory management systems allows warehouse owners to save money and prevent losses in human labor. These systems are as well ideal for meeting deadlines, customer requirements and providing responsive processing for the consumers. A successful flow of product can only be maintained if you know where your inventory is located, either locally or remotely. It helps you to enable product flow through the warehouse, and further on, to sellers and customers. You can meet consumers' needs and expand your operations by bringing together a wide range of professionals, enabling a flowing supply chain and developing a dependable, though efficient system. |

When your warehouse business is growing, a single facility becomes insufficient to meet your quickly growing needs. If every crevice in your primary facility is filled with goods and you hope that a second storage might ease the pressure causing you regular delays, inventory losses and poor packing damage, it is time to consider implementing

When your warehouse business is growing, a single facility becomes insufficient to meet your quickly growing needs. If every crevice in your primary facility is filled with goods and you hope that a second storage might ease the pressure causing you regular delays, inventory losses and poor packing damage, it is time to consider implementing